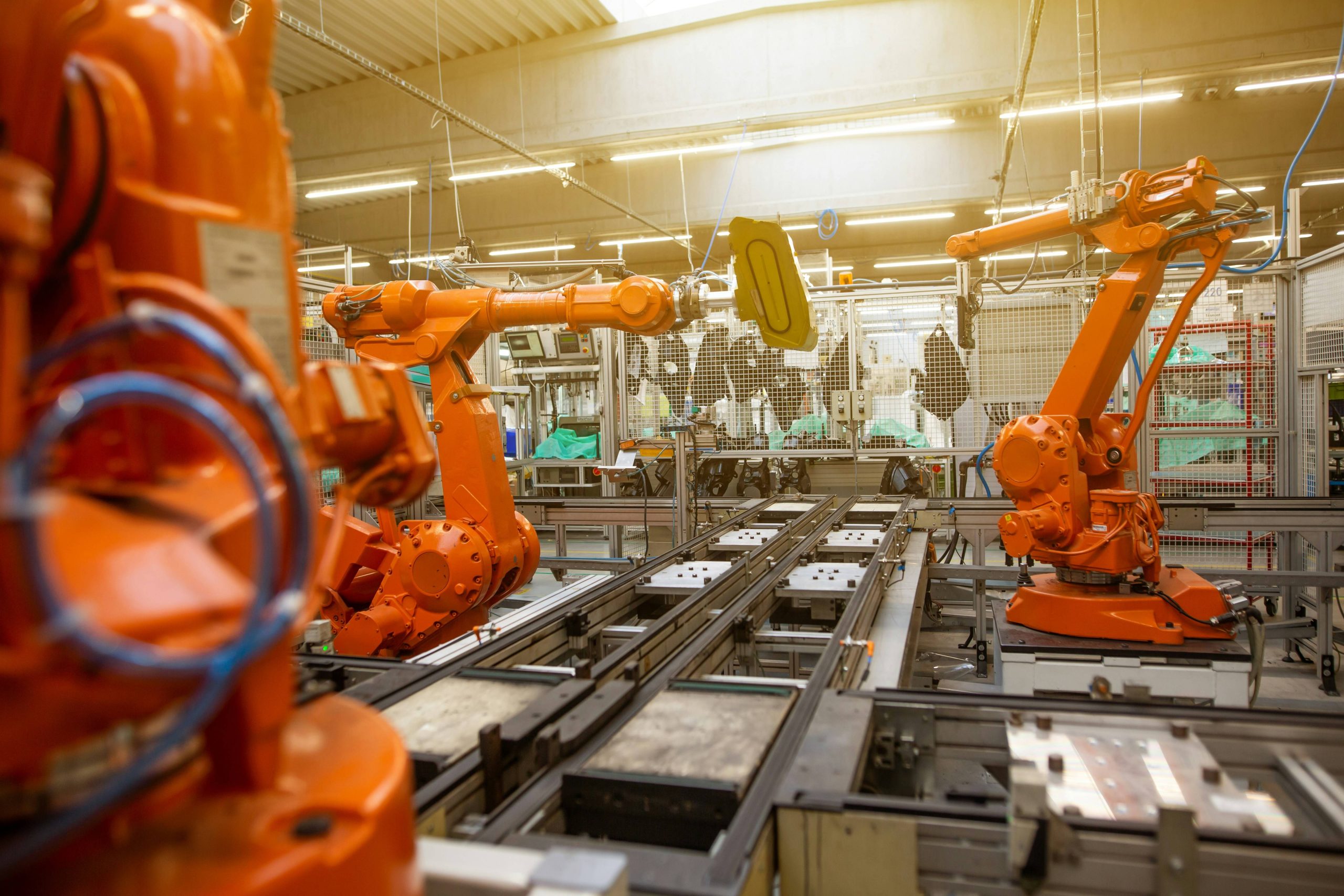

Industrial panel PC applications help factories work better by allowing real-time checks and automation. These systems gather and study data like temperature and pressure to keep things steady. They handle big amounts of data fast, helping make smart choices and improving work speed.

Automation with industrial panel PC applications cuts down delays and boosts dependability. These systems find and fix problems right away, keeping machines running well. With IoT features, they give advanced tools to watch and control factory work, making them very useful for today’s factories.

Using industrial panel PC applications gives you tools to work faster and easier, helping your factory do its best.

Key Takeaways

Industrial panel PCs are essential for real-time monitoring and automation, which helps speed up decision-making in factories.

Choose panel PCs with high IP ratings for durability in tough environments, ensuring they last longer and work reliably.

Opt for fanless designs to conserve energy and prevent dust buildup, reducing maintenance and operating costs.

Ensure that the panel PCs come with touchscreens that suit your needs for easier interaction in different factory settings.

Confirm compatibility with existing systems by checking operating systems and port availability, making setup easier and avoiding operational delays.

Key Features of Industrial Panel PCs

Durability for Tough Conditions

Industrial panel PCs are engineered to withstand harsh conditions. They perform well in environments with extreme temperatures, dust, or exposure to water. These devices typically feature high IP ratings, such as IP65 or higher, which ensure protection against dust and water.

Many panel PCs use SSDs instead of traditional hard drives. SSDs are more durable because they have no moving parts, which reduces the risk of failure. Robust designs also protect the devices from shocks and vibrations, making them ideal for factory environments.

Tip: Choose panel PCs without fans to avoid dust problems and keep them working longer.

Fanless and Energy-Saving Design

Fanless industrial panel PCs save energy and operate quietly. Without fans, they stay cooler and consume less power. This design also prevents dust from entering the system, which extends the device's lifespan. Many models feature processors like the Intel® Celeron® Elkhart Lake , which offers a good balance between performance and energy efficiency.

Feature | Description |

|---|---|

Uses Less Power | Fanless designs generate less heat, requiring less energy. |

Lasts Longer | Remaining cooler improves long-term reliability, extending device lifespan. |

Energy-efficient panel PCs help lower electricity costs. They also prevent overheating, which minimizes downtime and increases operational efficiency.

Easy-to-Use Touchscreens

Touchscreens make industrial panel PCs simple to operate. You can tap, swipe, or zoom to control them. Bright screens make them easy to see, even in sunny areas.

Touchscreens use resistive or capacitive technology. Capacitive screens are faster and allow multi-touch gestures. Resistive screens work well if you wear gloves. Bigger touch areas are better. They help reduce mistakes and speed up work.

Note: Pick a panel PC with the touchscreen type that fits your needs.

Seamless Integration with Industrial Systems

Industrial panel PCs are designed for easy integration with existing systems. They support operating systems such as Windows, Linux, and Android, making them flexible and easy to use. This means you can continue using your current software without additional costs or complicated adjustments.

Panel PCs come with various I/O ports, including USB, RS232, RS485, and Ethernet, to connect different devices. These ports enable seamless communication between sensors, controllers, and machines. For example, Ethernet ports facilitate rapid data sharing within your network, improving overall system performance.

Software compatibility is key for system integration. Many panel PCs support industrial protocols like Modbus and OPC UA. These protocols help them connect with PLCs and automation tools.

Tip: Check if the panel PC's operating system and ports match your equipment. This avoids problems and saves time.

With these features, panel PCs make system upgrades easier. They improve your factory without stopping your work. This smooth integration boosts efficiency and reduces downtime, keeping productivity steady.

Panel PC Applications in Manufacturing

Real-Time Process Monitoring and Control

Industrial panel PCs help watch and manage factory work instantly. They gather and show data fast, helping quick decisions. These devices link sensors to workers, showing live production details. This keeps work smooth and lowers mistakes.

Panel PCs show trends and problems clearly. They connect with PLCs and SCADA systems for automatic changes. This setup improves work and helps fix machines before they break. For example, checking sensor data can stop machine failures, cutting downtime by 22% in busy factories.

Tip: Pick strong panel PCs for tough factory conditions to ensure they last.

Automation and Workflow Optimization

Panel PCs make factory work faster with automation. They reduce the need for people to do tasks, speeding up production. For example, smart panel PCs use AI to save energy and materials by spotting waste.

They find defects quickly, improving product quality and reducing errors. Panel PCs also keep workers safe by checking the environment and following safety rules. Studies show 80% of factories now use digital tools like panel PCs to work better.

Metric | Description |

|---|---|

Faster Workflows | Automation cuts down manual work, making production quicker. |

Better Resource Use | AI finds and fixes wasted energy or materials. |

Improved Product Quality | Live checks ensure products are made correctly. |

Safer Workplaces | Monitoring keeps workers safe and follows safety rules. |

Data Collection and Analysis for Decision-Making

Industrial panel PCs are great at collecting and studying data. They gather information from different places and show it simply. For example, they work with cloud systems to share data and make decisions faster.

Good data collection lowers surprise repair costs by 30% in chemical factories. Panel PCs also predict problems by studying patterns, stopping issues early. This reduces downtime and makes work smoother.

Evidence Description | Statistic |

|---|---|

Downtime reduction in busy factories | 18-22% |

Companies using industrial PCs for predictive maintenance | 67% |

Lower unplanned repair costs in chemical plants | 30% |

Note: Use panel PCs with easy controls to make data analysis simple and save training time.

Quality Assurance and Inspection

Industrial panel PCs help keep products high-quality in factories. They work with advanced systems to find defects and meet standards. For example, they support machine vision by using USB 3.0 for quick data sharing. GPIO helps control many cameras, while x16 PCIe Gen3 GPUs process data fast.

Panel PCs also check products with strict quality tests. Below are some tests they assist with:

Quality Test | Description |

|---|---|

High and Low-Temperature Resistance Test | Makes sure products survive extreme heat or cold, finding flaws. |

Waterproof Test | Checks if devices work well in wet conditions, important for factories. |

Usability Testing | Tests how easy products are to use, ensuring simple controls for workers. |

These features make quality checks faster and more accurate. They lower mistakes and improve inspections, helping products meet rules.

Tip: Pick panel PCs that support many cameras for quicker inspections.

Inventory and Supply Chain Management

Industrial panel PCs make managing inventory and supply chains simpler. They give live updates to track materials and improve workflows. For example, panel PCs with 5G cut material errors by 40%, as shown in a South Korean battery factory.

Here’s how panel PCs help with inventory:

Live updates boost production by 12%, as seen in a Taiwanese factory.

Better scanning improves tracking by 34%, based on DHL studies.

EBR systems cut record mistakes by 75%, ensuring accuracy and following rules.

Using these tools reduces errors, saves money, and improves accuracy. Industrial panel PCs are key for modern factories and supply chains.

Note: Use panel PCs with cloud features to share data easily across your supply chain.

Selecting and Using Industrial Panel PCs

Assessing Your Factory’s Needs

Before selecting a panel PC, evaluate your factory’s specific conditions. Consider factors such as dust, moisture, and temperature exposure. For example, a factory located in a humid environment may require a panel PC with an IP65 rating for added protection against moisture and dust.

Temperature is also important. Most panel PCs work between -10℃ and 60℃. But regular LCD screens may not work well outside. Choose features like shockproof designs and touchscreens that fit your needs.

Metric | What It Does |

|---|---|

IP Ratings | Keeps out dust and water in tough places. |

Temperature Range | Makes sure it works in hot or cold areas. |

Connection Options | Links to machines and sensors easily. |

Tip: Think about your factory's special needs to pick the right panel PC.

Picking the Right Features

Choose features that match your tasks for better performance. If you need high power, pick strong processors for tasks like machine vision. For simple jobs like scanning, less power is fine.

Screen size matters too. A 15-inch screen with good resolution is great for detailed work. Smaller screens are fine for basic tasks.

Feature | Why It Matters |

|---|---|

Processing Power | Needed for tasks like inspections or controls. |

Size and Space | Make sure it fits where you’ll install it. |

Connection Ports | Look for USB, Ethernet, or wireless options. |

Note: Don’t pick features you don’t need. It saves money.

Making Sure It Works with Your Systems

Panel PCs should work well with your current setup. Check if the operating system supports your software. For example, Windows panel PCs work with most factory programs.

Look at the ports. Many panel PCs have USB, RS232, and Ethernet ports to connect to machines. Custom options can also help match your setup.

Tip: Test the panel PC with your system first to avoid problems.

Training Teams for Effective Utilization

Teaching your team is key to using industrial panel PCs well. Without training, even great technology might not work as expected. Start by showing basic functions of the panel PC. Teach how to use the touchscreen, navigate menus, and find important features.

Practice helps workers feel confident. Let them use the panel PCs in a safe setting. For example, pretend to monitor machines or change settings. This shows how the system fits into their daily work.

Make simple guides or quick tips for common tasks. These save time and help during problems. You can also create videos for those who learn better by watching.

Keep training updated regularly. When new software or upgrades come, teach your team about them. Plan refresher sessions to review skills and explain new tools.

Tip: Let workers ask questions and share ideas during training. This makes learning easier and more effective.

Partnering with Trusted Suppliers

Picking the right supplier for industrial panel PCs is very important. Good suppliers make products that last in tough factory conditions. Their panel PCs are strong and dependable.

Choose suppliers that use fanless cooling systems. This keeps the devices cool and working longer. Compact designs and touchscreens also save space, which is helpful in factories.

Trusted suppliers often include HMI/SCADA software in their products. This software helps monitor and control work in real-time. Their panel PCs also connect easily with other systems, supporting modern factory needs.

Why Trusted Suppliers Matter:

Strong performance in tough environments.

Space-saving designs with easy-to-use touchscreens.

Better efficiency with built-in software.

Support for digital upgrades with advanced connections.

Working with a reliable supplier gives you quality products and support. This helps your factory stay productive and competitive.

Note: Check reviews and case studies about suppliers before choosing one. This ensures they are trustworthy.

Industrial panel PCs help factories work better by boosting efficiency. They lower downtime and improve how operations are controlled. These devices collect live data, helping you make smart choices and simplify tasks. For instance, they find reasons for downtime and show what's happening on the shop floor.

Metric | Description |

|---|---|

Production Efficiency | Tracks live production data to make manufacturing smoother. |

Downtime Tracking | Finds and groups downtime causes, reducing unexpected machine stops. |

Real-time Data Collection | Shows shop floor activities clearly, helping better decisions and control. |

Tip: Learn how panel PCs can improve workflows and increase factory productivity.

FAQ

1. Which industries use industrial panel PCs the most?

Factories, logistics, food production, and medicine benefit greatly. These PCs handle tough conditions and improve automation. They help with live monitoring, quality checks, and managing inventory.

2. How can I take care of an industrial panel PC?

Wipe the screen gently with a soft cloth. Check cables often. Use covers in extreme places. Fanless models stop dust buildup, making them easier to maintain.

Tip: Always follow the maker’s care guide for the best results.

3. Can industrial panel PCs work with IoT devices?

Yes, they can connect to IoT devices. They link to sensors, controllers, and cloud systems using Wi-Fi, Ethernet, or protocols like Modbus. This lets you control and monitor work remotely.

4. Are industrial panel PCs adjustable to my needs?

Yes, many suppliers let you customize them. You can pick screen size, processor, and ports. Some even pre-install software to make setup easier.

Note: Talk to the supplier about your needs for the best setup.

5. How do I pick the right industrial panel PC?

Think about your factory’s conditions. Look for features like IP ratings, temperature limits, and connection options. Match the specs to your tasks, like automation or data tracking.

Tip: Try the panel PC in your factory before buying more.