Industrial panel PCs are tough computers made for hard jobs. They have strong aluminum cases and panels that block dust and water. These PCs help automation by wIndustrial panel PCs are rugged and durable devices built to withstand tough environments. With robust aluminum enclosures and IP65-rated panels, they protect against dust, water, and other harsh conditions. These PCs play a crucial role in automation by monitoring systems in real time, enhancing control, and reducing manual labor. Their intuitive touchscreens improve operational speed and reliability in industrial settings, helping businesses streamline processes and minimize errors.

Key Takeaways

Industrial panel PCs are strong and can handle tough environments. They work well in factories and outside areas.

Their touch screens make jobs easier and quicker. They also help find mistakes fast, keeping workers safe.

PCs without fans use less energy and break less often. This makes them last longer and saves money over time.

Key Features of Industrial Panel PCs for Automation and Control

Rugged Construction

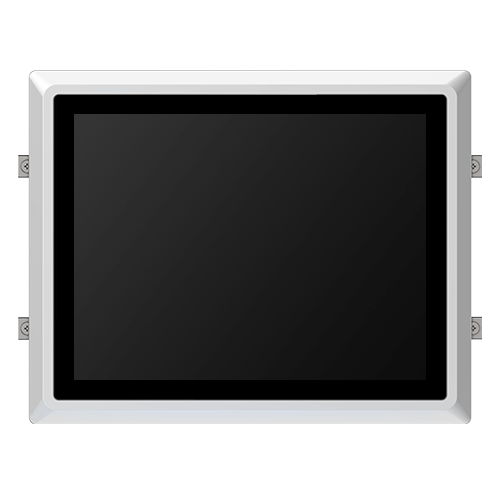

Industrial panel PCs are engineered for extreme conditions. Their robust construction safeguards them from shocks, vibrations, and severe weather. Designed to meet military-grade standards like MIL-STD-810G, they are built for long-term durability. With an IP65 rating, they offer reliable protection against dust and water, making them ideal for industrial environments. These devices exhibit exceptional reliability, with failure rates under 0.5% annually, ensuring consistent performance even in the harshest conditions.

Touch Screen Display

The touchscreen is a vital feature of industrial panel PCs. By automating tasks and reducing manual input, it simplifies complex operations. The intuitive interface allows for quicker and more accurate workflows, improving productivity. Touchscreens also help operators quickly identify errors, enhancing safety. With crystal-clear displays, these PCs enable real-time monitoring, immediate adjustments, and enhanced control, which reduces delays and optimizes system performance.

Fanless Design

Fanless designs offer several key benefits in industrial panel PCs. By utilizing passive cooling, these systems operate efficiently even in extreme conditions. The absence of moving parts reduces the risk of mechanical failure and minimizes dust buildup, ensuring longer-lasting performance. Additionally, fanless industrial panel PCs are energy-efficient, reducing operating costs and increasing reliability.

Benefit | Description |

|---|---|

Lower Energy Use | Fanless PCs save energy and cut costs while staying cool. |

Less Breakdowns | No moving parts mean fewer hardware problems and overheating. |

Better Durability | Passive cooling stops dust and keeps the PC working well in tough places. |

Expandability

These PCs are built to grow with your needs. You can add memory, new ports, or extra features easily. Modular designs let you change the system to fit your tasks. This makes them useful for a long time.

Connectivity Options

Good connections are key for industrial work. These PCs connect to sensors, machines, and networks easily. In factories, they manage production lines smoothly. In oil plants, they handle equipment in tough conditions. Their strong connections help devices work together, improving control and efficiency.

Mounting Flexibility

You can mount these PCs in many ways to fit your space. Put them on walls, panels, or inside cabinets. This flexibility saves space and makes them easy to use. Whether you need a small setup or a custom one, these PCs adjust to your needs. They are a smart choice for different industrial jobs.

Types of Industrial Panel PCs

Industrial panel PCs come in different types for various jobs. Knowing these types helps you pick the best one for your needs.

All-in-One Industrial Panel PCs

All-in-One panel PCs combine a screen and computer in one device. This saves space and makes setup easier. They have tough cases, touchscreens, and many connection options. These PCs work well in places needing small and efficient systems.

Feature | Description |

|---|---|

Touchscreen Technology | Lets users interact directly with the screen for easier use. |

Ruggedized Enclosures | Keeps the PC safe from dust, water, shaking, and heat. |

Connectivity Options | Includes USB, Ethernet, and wireless for easy connections. |

Configurations | Offers different memory and processing power for specific tasks. |

Modular Industrial Panel PCs

Modular panel PCs are flexible and can grow with your needs. You can add or upgrade parts like memory or ports. This makes them great for industries that change over time. Their strong build works well in tough places, and they connect easily to other devices.

Feature | Description |

|---|---|

Role as HMI | Acts as a control center for machines, showing real-time data. |

Durability | Built tough to handle dust, water, and extreme temperatures. |

Connectivity Options | Includes USB, Ethernet, and wireless for smooth connections. |

Customization Capabilities | Lets you add extra parts to fit your needs. |

Embedded Industrial Panel PCs

Embedded panel PCs are small and made for specific tasks. They fit into machines easily, saving space. These PCs are reliable and work well in tough conditions. They handle wide temperature ranges and resist shocks, ensuring they perform well.

These PCs collect data for IoT systems.

They share real-time info with connected devices.

They work with IoT platforms for data analysis and remote control.

Feature | Description |

|---|---|

Rugged Design | Made to last in tough places with fanless cooling. |

Environmental Adaptability | Works in extreme temperatures and resists shocks. |

Compliance with Standards | Follows safety and environmental rules. |

Industry Certifications | Certified for use in areas like railways and ships. |

Portable Industrial Panel PCs

Portable panel PCs are easy to carry and use. They are small and light, perfect for jobs that need movement. These PCs are tough, have touchscreens, and use fanless cooling. They connect through Wi-Fi or cellular, helping with IIoT tasks and improving efficiency.

Feature | Description |

|---|---|

Specialized Design | Made for industrial jobs, not regular office use. |

Touchscreen Technology | Works with gloves, using capacitive or resistive screens. |

Ruggedized Construction | Stronger than office PCs, built for harsh environments. |

Fanless Cooling Technology | Uses heatsinks to stay cool without fans, great for dusty areas. |

Compact Size | Saves space and reduces extra wires on factory floors. |

Connectivity Options | Includes LAN, I/O, Wi-Fi, and cellular for IIoT tasks. |

Long-term Investment | Built to last, lowering repair costs and system issues. |

Applications of Industrial Panel PCs in Automation

Automation and Control

Industrial panel PCs help with automation and control tasks. They monitor machines and check how they are working. These PCs can find problems early and prevent breakdowns. This saves money on repairs and keeps machines running longer. For example, in car factories, they manage production to keep things running smoothly. Their strong design makes them perfect for jobs needing accuracy and reliability.

Data Collection and Analysis

Collecting and studying data is important for better factory work. Industrial panel PCs gather data from machines and sensors in real-time. They turn this data into useful information for better decisions. For instance, in food factories, they show live data to ensure quality and smooth processes. Their ability to handle lots of data helps improve performance and meet automation goals.

Human-Machine Interfaces (HMI)

Human-machine interfaces let people easily control machines. These interfaces give real-time updates and allow quick changes. They fit into production lines to manage important tasks and reduce manual work. By automating simple jobs, they lower mistakes and improve efficiency. They also provide reports and data analysis to help make better decisions and improve operations.

Performance Metric | Description |

|---|---|

Real-time Control and Monitoring | Shows live data and control settings to boost efficiency. |

Integration into Production Lines | Manages key tasks for smooth workflows and quick fixes. |

Process Automation and Optimization | Cuts down on manual work and errors by automating tasks. |

Data Analysis and Reporting | Collects data to find trends and make smarter decisions. |

Quality Control

Industrial panel PCs improve quality checks by working with sensors. They watch important details and analyze data to stop defects. This keeps manufacturing standards high and reduces waste. For example, in medicine factories, they ensure safety and precision in production. Their dependability in quality checks makes them essential for automation.

Sector | Application Description | Market Growth Trend |

|---|---|---|

Automotive | Helps monitor and manage manufacturing processes. | Growing need for automation. |

Food and Beverage | Used for live data display and process control. | More factories using automation. |

Pharmaceuticals | Ensures safety and efficiency in making medicines. | Rising demand for industrial PCs. |

Industrial panel PCs are important for making work easier. Their strong build, simple screens, and flexibility help many industries like factories and medicine. The market is expected to grow from $4.59 billion in 2023 to $6.41 billion by 2030. This shows they are becoming more useful. Use these PCs to improve your industrial tasks.

FAQ

How are industrial panel PCs different from regular computers?

Industrial panel PCs are designed to perform in demanding environments. Unlike regular computers, they feature rugged enclosures, touchscreens, and fanless cooling systems, which make them far more reliable and durable in harsh industrial conditions.

Can you change industrial panel PCs for special jobs?

Yes, you can add memory, ports, or other features. This helps them work well for your specific industrial tasks.

Can industrial panel PCs be used outside?

Many industrial panel PCs are built for outdoor use. Their strong cases and IP ratings keep them safe from dust, water, and bad weather.