Industrial PCs for Industrial Vision play a crucial role in helping vision systems check products accurately in factories. They process large data quickly with strong processors and GPUs. For example:

Spending on edge computing will go over $250 billion.

Major oil refineries generate 1 TB of sensor data every day.

By integrating industrial PCs, vision systems can detect defects in real-time, significantly improving product quality checks through advanced image processing, AI tools, and equipment monitoring solutions.

Key Takeaways

Industrial PCs are made to handle tough factory conditions. They work well in very hot, cold, or dusty places.

These strong computers handle big data fast. This helps check product quality quickly, lowering mistakes and making better products.

Adding AI and edge computing to industrial PCs finds defects faster. It also helps make quicker choices, saving time and cutting waste.

The Role of Industrial PCs in Industrial Vision Systems for Automated Quality Control

What Are Industrial PCs and Why Are They Important?

Industrial PCs are special computers made for tough factory work. Unlike regular computers, they work well in hot, cold, or dusty places. They are built strong to keep running without stopping. These characteristics make industrial PCs indispensable for machine vision systems, where they manage and process large amounts of image data to detect defects and ensure real-time quality control.

Industrial PCs are important because of what they can do. For example, they help machines check packaging to make sure products are good. They also help test systems and predict risks in factories. The table below shows why they are key for vision systems:

Feature/Use | What It Does |

|---|---|

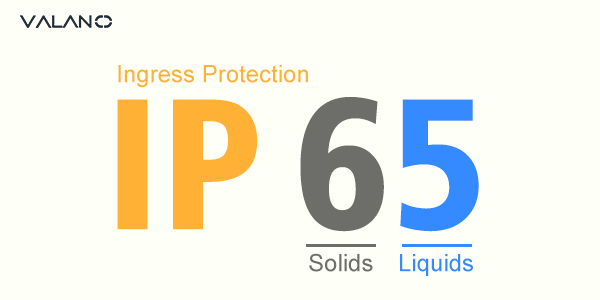

Works in Harsh Conditions | Handles heat, cold, and tough environments. |

Handles Vibrations | Stays steady in busy factory settings. |

Keeps Out Dust | Fanless design stops dust from causing issues. |

Helps in Manufacturing | Guides robots and powers machine vision tools. |

Improves Quality Checks | Automates inspections to save time and effort. |

Manages Data Remotely | Collects and monitors data in real-time. |

How Industrial PCs Work with Vision System Parts

Industrial PCs integrate seamlessly with various components of machine vision systems, such as cameras, algorithms, and robotic controls. Their advanced processors enable fast data handling, ensuring smooth and efficient operations in real-time. These PCs enable real-time image processing and defect detection, significantly improving inspection accuracy and speed.

For example, industrial PCs with many processors can do several tasks at once. This helps them quickly analyze images and find defects. They also reduce delays, making inspections faster and more accurate. These features make vision systems more efficient and reliable.

Why Industrial PCs Are Great for Automated Inspections

Industrial PCs have features that make them perfect for automated checks. Their powerful processors and GPUs handle hard tasks like AI and deep learning. This helps them find tiny problems in products.

They are also very reliable. Industrial PCs keep working even in tough conditions, so factories don’t stop. They process data quickly, which is important for real-time checks. Plus, their easy-to-use controls help workers adjust systems easily.

Using these features, you can improve vision systems for better inspections and quality control.

Key Benefits of Using Industrial PCs for Automated Quality Control

Real-Time Quality Inspection and Image Processing with Industrial Vision Systems

Industrial PCs help factories check product quality instantly. They use machine vision to spot problems fast without slowing work. These systems inspect items quickly without touching them, reducing mistakes and keeping quality steady.

For example, industrial PCs with smart image tools can find tiny flaws. They detect scratches, misaligned parts, or missing pieces in seconds. This ensures every product is perfect before leaving the factory. Automated checks improve accuracy, cut waste, and save time and money.

Enhanced Processing Power for Machine Vision in Automated Inspection

Industrial PCs are very powerful for machine vision tasks. They have fast memory and modern ports like USB 3.0. This helps them handle big data and make quick decisions.

For instance, industrial PCs with special GPUs can spot tricky patterns. They find defects that people might miss and check many parts quickly. They can inspect hundreds of items each minute without errors. Faster processing also helps factories adjust to changes easily.

Edge Computing and AI Integration in Industrial PCs for Faster Quality Checks

Industrial PCs are built to endure the harsh environments commonly found in factories. They can operate in extreme temperatures, handle vibrations, and keep working in dusty conditions, which helps ensure that production runs without interruptions.

What makes these PCs even more valuable is their ability to predict potential issues before they cause problems. By continuously analyzing sensor data, they can identify early signs of trouble, allowing factories to plan maintenance during scheduled downtime. This proactive approach prevents unexpected breakdowns, improves operational efficiency, and ensures that quality checks remain consistent.

Applications of Industrial PCs for Automated Quality Control in Manufacturing

Finding and Sorting Defects in Production Lines

Industrial PCs help find and sort defects on production lines. They work with cameras to check products for flaws. These systems make sure inspections are fast and accurate.

For example, Artemis Vision made a system using industrial PCs and cameras. It checks dual-pane glass for defects quickly and meets standards. With GPUs and deep learning, industrial PCs can spot tricky defects better.

Predicting Maintenance and Watching Machines

Industrial PCs help predict when machines need fixing. They use sensors to watch things like heat and vibrations. These PCs process the data fast to plan repairs before breakdowns.

A car factory cut downtime by 83% with predictive maintenance.

Repair costs dropped 47%, and product quality went up 23%.

With industrial PCs, you can track machine health on easy dashboards. This keeps machines running longer and avoids sudden stops.

Making Inspections Faster and Better

Industrial PCs make inspections faster and more accurate. They let vision systems check hundreds of items every minute without mistakes. By quickly using sensor data, they help adjust production instantly.

One study showed upgrading to industrial PCs improved speed and quality. This proves how industrial PCs with AI make inspections better. Picking the right industrial PCs can save time, reduce waste, and improve results.

Technological Advancements in AI-Powered Machine Vision

AI Integration for Smarter Quality Control

AI-powered vision systems have changed how factories check quality. By using AI with industrial PCs, factories can watch production live. They can find problems right away and fix them early. This helps make better products and reduces waste. For example, AI systems can look at product images and find flaws people might miss. These systems make work faster, improve results, and keep customers happy.

AI also helps machines adjust on their own during production. This means no one needs to stop and fix things manually. In industries like car-making and electronics, AI systems are now very important for keeping work precise and efficient.

Edge Computing for Low-Latency Data Processing

Edge computing with industrial PCs makes data processing super fast. It lets factories handle data nearby instead of waiting for faraway servers. This saves time and helps make quick decisions. For example, robots using edge computing can act right away, boosting production by 30%.

A report showed 80% of companies using edge computing had fewer delays. It also cut energy use by 35%, saving money. With edge computing, factories can check quality faster and more reliably.

Deep Learning for Complex Pattern Recognition in Quality Control

Deep learning helps industrial PCs find tricky patterns during quality checks. It works well in industries like electronics, fabrics, and cars. For instance, AI tools can spot missing parts on circuit boards, sewing mistakes in clothes, or tiny cracks in engines.

Using industrial PCs with GPUs, factories can take clear images and study small details. This ensures even tiny flaws are caught, making products more dependable.

The Future of Industrial Vision Systems in Manufacturing

The future of vision systems in factories looks exciting with AI and computer vision. Experts say the market will grow by 7.64% yearly until 2032. New trends include 3D vision, which helps robots work better and improves quality checks.

Fast data processing will help factories adjust quickly to changes. Cloud-based tools are also becoming popular because they are easy to scale and use from anywhere. As factories go digital, picking the right industrial PCs will be key to staying ahead.

Industrial PCs are important for today’s factory vision systems. They work well in tough conditions and process data quickly. This helps find defects right away. With industrial PCs, machines work faster and make fewer mistakes. They also save money by cutting waste and keeping production steady. As technology gets better, industrial PCs will help factories improve quality checks and stay reliable.

FAQ

What is vision-guided robotics, and how does it work with industrial PCs?

Vision-guided robotics uses cameras to help robots see and move. Industrial PCs handle this data to guide robots for tasks like building and checking items.

How do industrial PCs help factories make quick decisions?

Industrial PCs process data fast to help systems act quickly. This keeps production smooth, checks quality, and adjusts to changes right away.

Can industrial PCs make object recognition better in machines?

Yes, industrial PCs use smart tools to recognize objects clearly. They help machines find and sort items, even in tricky situations.